Elegant Natural Stones private Limited

- होम पेज

- कंपनी प्रोफाइल

-

हमारे उत्पाद

- संगमरमर

- ग्रीन मार्बल

- मार्बल टाइल्स

- इंडियन मार्बल स्लैब

- सफेद संगमरमर की टाइलें

- इंडियन मार्बल फ्लोर स्लैब

- इंडियन मार्बल

- ग्रीन इंडियन मार्बल स्टोन्स

- प्राकृतिक पत्थर की टाइलें

- इंडियन मार्बल स्टोन

- इंडियन मार्बल फ्लोर टाइल्स

- पॉलिश मार्बल टाइल

- इंडियन मार्बल टाइल्स

- मार्बल स्टोन्स

- ब्लैक मार्बल टाइल्स

- इंडियन मार्बल टाइल पैटर्न

- मार्बल ब्लॉक

- मार्बल फ्लोर स्लैब

- मार्बल फ़्लोरिंग स्लैब

- ब्लैक गैलेक्सी मार्बल

- मार्बल फ्लोरिंग टाइल्स

- राजस्थानी मार्बल

- मार्बल टाइल डिजाइन

- संगमरमर की रसोई के फर्श

- कस्टम मार्बल टेबल टॉप

- मार्बल टाइल स्लैब

- पॉलिश मार्बल फ्लोर टाइल

- मार्बल स्लैब

- संगमरमर के फर्श के डिजाइन

- मार्बल टेबल टॉप डिज़ाइन

- मार्बल फ्लोरिंग पैटर्न

- मार्बल फ्लोरिंग

- मार्बल टेबल टॉप स्लैब

- मार्बल टाइल पैटर्न

- इंडियन टाइल मार्बल पैटर्न्स

- मार्बल स्टोन डिज़ाइन्स

- मार्बल टाइल पैटर्न डिजाइन

- ग्रेनाइट

- इंडियन ग्रेनाइट

- ग्रेनाइट टाइल टेबल टॉप डिज़ाइन

- ग्रेनाइट टाइल फ़्लोरिंग

- ग्रेनाइट इंडियन स्लैब

- गैलेक्सी ग्रेनाइट स्लैब

- ग्रेनाइट टाइल डिजाइन

- ग्रेनाइट स्टोन

- ग्रेनाइट पैटर्न्स

- डिज़ाइनर ग्रेनाइट फ़्लोरिंग

- ग्रेनाइट फ़्लोरिंग डिज़ाइन

- स्नो व्हाइट ग्रेनाइट

- प्राकृतिक ग्रेनाइट फ़्लोर टाइल

- ब्लैक ग्रेनाइट फ़्लोर टाइल

- ग्रेनाइट स्लैब

- ग्रेनाइट फ़्लोरिंग

- ब्लैक ग्रेनाइट

- ब्लैक पॉलिश प्राकृतिक ग्रेनाइट फ़्लोर टाइल

- इंडियन ग्रेनाइट स्टोन स्लैब

- ग्रेनाइट काउंटर टॉप

- ग्रेनाइट कट साइज स्लैब

- ग्रेनाइट ब्लॉक

- इंडियन ग्रेनाइट स्लैब

- इंडियन ग्रेनाइट स्लैब

- इंडियन ग्रेनाइट फ़्लोरिंग स्लैब

- इंडियन ग्रेनाइट स्टोन

- ग्रेनाइट फ़्लोरिंग पैटर्न

- ग्रेनाइट स्टोन डिज़ाइन

- ग्रेनाइट टाइल पैटर्न

- इंडियन ग्रेनाइट मार्बल

- ग्रेनाइट टेबल टॉप

- ग्रेनाइट स्टोन स्लैब

- ग्रेनाइट फ़्लोर स्लैब

- ग्रेनाइट टाइल्स

- इंडियन ग्रेनाइट टाइल्स

- बाल्टिक ब्राउन ग्रेनाइट

- कश्मीर्स गोल्ड ग्रेनाइट

- राजस्थान ब्लैक ग्रेनाइट

- अलास्का व्हाइट ग्रेनाइट

- अलास्का ब्लू ग्रेनाइट

- अम्बा व्हाइट ग्रेनाइट

- एप्पल ग्रीन ग्रेनाइट

- बाला फ्लावर ग्रेनाइट

- बैश पारादीसो ग्रेनाइट

- ब्लैक मार्क्विनो ग्रेनाइट

- ब्लैक पर्ल ग्रेनाइट

- ब्लू ग्रेनाइट

- ब्लू पर्ल ग्रेनाइट

- ब्राज़ीलियाई ग्रेनाइट

- ब्राउन पर्ल ग्रेनाइट

- बटरफ्लाई ब्लू ग्रेनाइट

- कैट्स आई ग्रेनाइट

- चीमा पिंक ग्रेनाइट

- चीमा पिंक ग्रेनाइट

- चेरी ब्राउन ग्रेनाइट

- क्लासिक पारादीसो ग्रेनाइट

- कॉफी ब्राउन ग्रेनाइट

- कोलंबो जुपराना ग्रेनाइट

- कॉपर सिल्क ग्रेनाइट

- डेजर्ट ग्रीन ग्रेनाइट

- बलुआ पत्थर

- सैंडस्टोन फ़्लोरिंग स्लैब

- सैंडस्टोन स्लैब

- रफ सैंडस्टोन स्लैब

- प्राकृतिक बलुआ पत्थर

- सैंडस्टोन फ़्लोर स्लैब

- सैंडस्टोन डिज़ाइन्स

- प्राकृतिक पत्थर का फर्श

- सैंडस्टोन गार्डन फ़्लोरिंग

- प्राकृतिक सैंडस्टोन फ़्लोरिंग

- इंडियन सैंडस्टोन फ़्लोरिंग

- सैंडस्टोन फ़्लोरिंग डिज़ाइन

- सैंडस्टोन फ़र्श फ़्लोरिंग

- इंडियन सैंडस्टोन स्लैब

- इंडियन सैंडस्टोन स्लैब

- इंडियन सैंडस्टोन

- रवीना सैंडस्टोन

- इंडियन सैंडस्टोन

- सैंडस्टोन स्लैब

- सैंडस्टोन फ़्लोरिंग

- प्राकृतिक बलुआ पत्थर का फर्श

- रफ सैंडस्टोन ब्लॉक्स

- आगरा रेड सैंडस्टोन

- ऑटम ब्राउन सैंडस्टोन

- बेज सैंडस्टोन

- चॉकलेट सैंडस्टोन

- धौलपुर बेज सैंडस्टोन

- धौलपुर रेड सैंडस्टोन

- फॉसिल मिंट सैंडस्टोन

- फॉसिल सैंडस्टोन

- कांडला ग्रे सैंडस्टोन

- पैंथर सैंडस्टोन

- पिंक सैंडस्टोन

- रेनबो सैंडस्टोन

- रेनबो टीक सैंडस्टोन

- टीकवुड सैंडस्टोन

- टीक सैंडस्टोन

- राज ग्रीन सैंडस्टोन

- रवीना सैंडस्टोन

- यलो मिंट सैंडस्टोन

- रियल ग्रे सैंडस्टोन

- कैमल डस्ट सैंडस्टोन

- धौलपुर व्हाइट सैंडस्टोन

- ललितपुर यलो सैंडस्टोन

- स्लेट पत्थर

- इंडियन स्लेट स्टोन स्लैब

- स्लेट स्टोन फ़्लोरिंग

- स्लेट स्टोन स्लैब

- स्लेट स्टोन्स

- प्राकृतिक स्लेट फ़्लोरिंग

- स्लेट स्टोन्स फ़्लोरिंग

- स्लेट स्टोन डिज़ाइन्स

- स्लेट स्टोन पैटर्न्स

- प्राकृतिक स्लेट स्टोन

- नॉर्थ इंडियन स्लेट स्टोन्स

- स्लेट स्टोन मार्बल

- स्लेट फ़र्श आँगन स्लैब

- सिल्वर ग्रे स्लेट स्टोन

- इंडियन स्लेट स्टोन पाविंग

- इंडियन स्लेट स्टोन्स स्लैब

- इंडियन स्लेट स्टोन

- स्लेट फ़र्श स्लैब

- इंडियन नेचुरल स्लेट स्टोन

- स्लेट स्टोन

- इंडियन स्लेट स्टोन्स

- चूना पत्थर

- बीदासर पत्थर

- इंडियन रेनफॉरेस्ट मार्बल

- इंडियन बिदासर स्टोन

- इंडियन बिदासर मार्बल

- इंडियन रेनफॉरेस्ट स्लैब

- भारतीय बिदासर स्लैब

- इंडियन रेनफॉरेस्ट मार्बल

- भारतीय बिदासर स्लैब

- बीदासर मार्बल स्लैब

- बिदासर मार्बल स्लैब

- रेनफॉरेस्ट मार्बल स्लैब

- रेनफॉरेस्ट मार्बल स्टोन्स

- रेनफॉरेस्ट मार्बल

- प्राकृतिक बिदासर स्टोन

- बिदासर स्टोन

- बीदासर फ्लोरिंग मार्बल

- बीदासर रेनफॉरेस्ट मार्बल

- बिदासर ग्रीन मार्बल स्लैब

- बीदासर ग्रीन मार्बल स्टोन

- बिदासर इंडियन मार्बल

- बीदासर मार्बल स्टोन

- बीदासर फ्लोरिंग

- बीदासर मार्बल स्लैब

- रेनफॉरेस्ट ग्रीन मार्बल

- प्राकृतिक बीदासर मार्बल्स

- बीदासर ग्रीन मार्बल

- बिदासर रेनफॉरेस्ट यलो मार्बल

- बिदासर रेनफॉरेस्ट ब्राउन मार्बल

- बिदासर स्टोन

- बिदासर मार्बल फ्लोरिंग

- बीदासर मार्बल

- बीदासर ब्राउन मार्बल

- बिदासर ग्रीन मार्बल स्लैब

- बीदासर रेनफॉरेस्ट ग्रीन मार्बल

- बीदासर फ्लोर पैटर्न्स

- बीदासर फ्लोर डिज़ाइन्स

- क्वार्टजाइट पत्थर

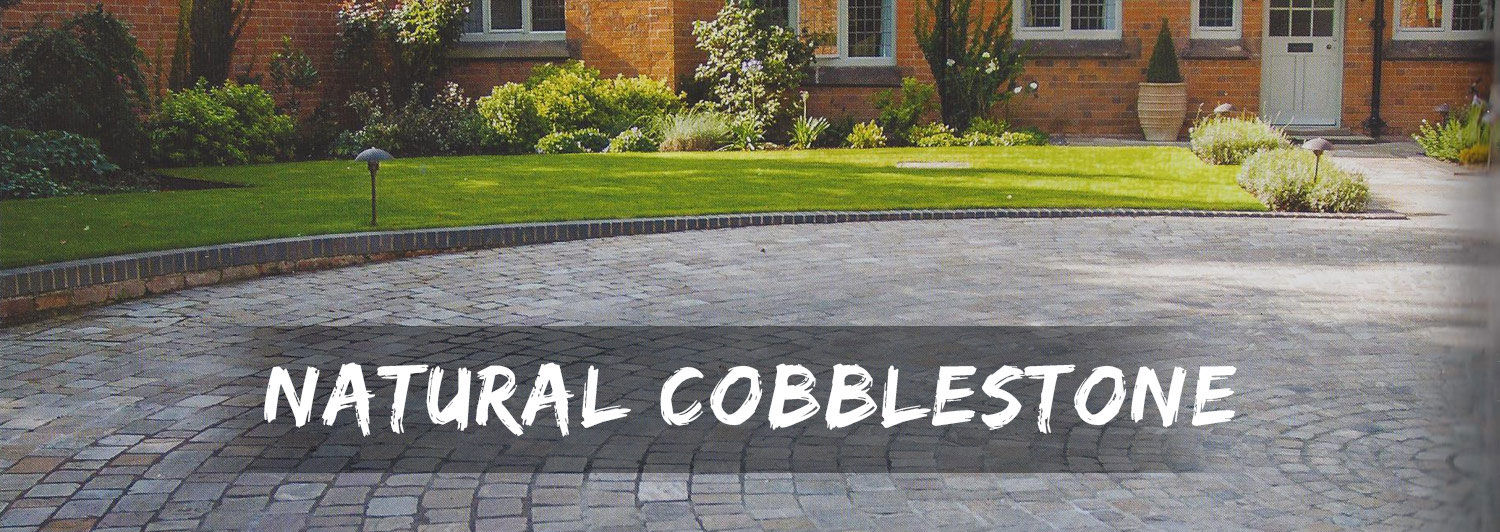

- प्राकृतिक कोबलस्टोन

- नदी के कंकड़

- पत्थर हस्तशिल्प

- इंडियन स्टोन हैंडीक्राफ्ट्स

- इंडियन सैंडस्टोन हैंडीक्राफ्ट्स

- स्टोन हैंडीक्राफ्ट आइटम

- सजावटी पत्थर के हस्तशिल्प

- संगमरमर के हस्तशिल्प

- स्टोन हैंडीक्राफ्ट्स

- संगमरमर के हस्तशिल्प आइटम

- संगमरमर के बर्तन

- स्टोन हैंडीक्राफ्ट्स डिज़ाइन

- स्टोन हैंडीक्राफ्ट्स पैटर्न्स

- पारंपरिक स्टोन हस्तशिल्प

- मार्बल फ्लावर पॉट

- स्टोन मार्बल हस्तशिल्प डिजाइन

- प्राकृतिक पत्थर के हस्तशिल्प

- बलुआ पत्थर के आधार

- पत्थर की जाली

- इंडियन मार्बल स्टोन जैलिस

- सैंडस्टोन जाली

- इंडियन मार्बल जलीस

- कोबल पैटर्न्स

- मार्बल जैलिस

- मार्बल स्टोन जैलिस

- नक्काशीदार संगमरमर की जाली

- संगमरमर पत्थर पर नक्काशी की जाली

- हाथ से नक्काशीदार संगमरमर की जाली

- फैंसी मार्बल स्टोन जालिस

- मार्बल स्टोन जैलिस पैटर्न

- डिजाइनर मार्बल स्टोन जालिस

- स्टोन जैलिस

- प्राकृतिक संगमरमर जाली डिजाइन

- पत्थर का लिबास

- इंडियन मार्बल पैनल्स

- इंडियन स्टोन पैनल्स

- इंडियन सैंडस्टोन पैनल्स

- स्टोन पैनल्स पैटर्न

- स्टोन पैनल्स मार्बल डिजाइन

- मार्बल पैनल्स

- स्टोन क्लैडिंग पैनल्स

- हाथ से नक्काशीदार पत्थर का पैनल

- स्टोन्स पैनल्स

- स्टोन वेनेर पैनल्स

- प्राकृतिक पत्थर के पैनल

- मार्बल स्टोन पैनल्स पैटर्न

- नक्काशीदार पत्थर के पैनल

- स्टोन पैनल्स टाइल्स

- पत्थर की चिमनियाँ

- इंडियन सैंडस्टोन फायरप्लेस

- इंडियन मार्बल फायरप्लेस

- इंडियन मार्बल स्टोन फायरप्लेस

- एंटीक मार्बल फायरप्लेस

- स्टोन फायरप्लेस मैन्टल्स

- स्टोन क्राफ्टेड फायरप्लेस

- स्टोन फायरप्लेस डिजाइन

- मार्बल फायरप्लेस

- स्टोन फायरप्लेस

- प्राकृतिक पत्थर की चिमनी

- संगमरमर पर नक्काशी वाले फायरप्लेस

- मार्बल स्टोन फायरप्लेस पैटर्न

- मार्बल स्टोन फायरप्लेस

- सैंड स्टोन फायरप्लेस

- संगमरमर की पेंटिंग

- पत्थर लगाने वाले

- इंडियन मार्बल स्टोन प्लांटर्स

- इंडियन नेचुरल स्टोन प्लांटर्स

- इंडियन स्टोन प्लांटर्स

- इंडियन सैंडस्टोन प्लांटर्स

- इंडियन मार्बल प्लांटर्स

- स्टोन गार्डन प्लांटर्स

- मार्बल स्टोन प्लांटर्स

- प्राकृतिक स्टोन प्लांटर्स

- स्टोन प्लांटर्स डिज़ाइन्स

- स्टोन फ्लावर प्लांटर्स

- आउटडोर स्टोन प्लांटर्स

- स्टोन बिग प्लांटर्स

- स्टोन प्लांटर्स पैटर्न्स

- स्टोन पॉट्स

- पत्थर के खंभे

- भारतीय प्राकृतिक पत्थर के स्तंभ

- भारतीय पत्थर के स्तंभ

- भारतीय संगमरमर के स्तंभ

- इंडियन स्टोन पिलर्स राउंड

- प्राकृतिक पत्थर के संगमरमर के खंभे

- प्राकृतिक पत्थर के खंभे

- संगमरमर के पत्थर के खंभे

- ग्रेनाइट स्टोन पिलर्स

- पत्थर के खंभे

- स्टोन पिलर्स डिजाइन

- नक्काशीदार पत्थर के खंभे

- सैंड स्टोन पिलर्स

- संगमरमर के कॉलम

- स्टोन पिलर्स पैटर्न

- पत्थर के फव्वारे

- इंडियन स्टोन फाउंटेंस

- इंडियन मार्बल स्टोन फाउंटेन

- स्टोन गार्डन फाउंटेन

- संगमरमर के फव्वारे

- संगमरमर के पत्थर के फव्वारे

- प्राकृतिक पत्थर के पानी के फव्वारे

- स्टोन फाउंटेन

- सैंडस्टोन गार्डन वाटर फाउंटेन

- छोटे पत्थर के फव्वारे

- प्राकृतिक पत्थर के फव्वारे

- संगमरमर के फव्वारे डिजाइन

- मार्बल स्टोन फाउंटेन डिजाइन

- स्टोन फाउंटेन डिजाइन

- स्टोन फाउंटेन पैटर्न

- पत्थर की आकृतियाँ

- इंडियन मार्बल स्टोन फिगर्स

- इंडियन स्टोन फिगर्स

- स्टोन एनिमल मूर्तियां

- स्टोन गॉड मूर्तियां

- संगमरमर की मूर्तियां

- हाथ से तैयार पत्थर की मूर्तिकला

- बलुआ पत्थर की मूर्ति

- प्राकृतिक संगमरमर पत्थर की आकृतियाँ

- स्टोन फिगर्स पैटर्न

- प्राकृतिक पत्थर की आकृतियाँ

- पत्थर की मूर्ति

- पत्थर की मूर्तियां

- स्टोन फिगर्स डिज़ाइन्स

- पत्थर की मूर्तिकला

- पत्थर की मेज के शीर्ष

- इंडियन मार्बल टेबल टॉप

- इंडियन स्टोन टेबल टॉप

- टेबल टॉप टाइल्स

- मार्बल स्टोन टेबल टॉप

- मार्बल स्टोन टेबल टॉप डिज़ाइन

- राउंड मार्बल टेबल टॉप

- स्टोन टेबल टॉप डिज़ाइन

- मार्बल टेबल टॉप

- प्राकृतिक मार्बल स्टोन टेबल टॉप

- मार्बल स्लैब टेबल टॉप

- प्राकृतिक स्टोन टेबल टॉप

- स्टोन टेबल टॉप स्लैब

- स्टोन टेबल टॉप

- इंडियन मार्बल स्टोन टेबल टॉप

- पत्थर के कर्ब

- पत्थर की दीवार पैनल

- इंडियन नेचुरल स्टोन वॉल पैनल्स

- इंडियन स्टोन वॉल पैनल्स

- इंडियन मार्बल वॉल पैनल्स

- वॉल पैनल्स स्टोन्स पैटर्न

- स्टोन टाइल्स

- वॉल पैनल्स स्टोन डिजाइन

- स्टोन वॉल टाइल्स

- स्टोन वॉल पैनल्स टाइल्स

- पारंपरिक स्टोन टाइल वॉल पैनल्स

- स्टोन वॉल पैनल्स

- सजावटी पत्थर की दीवार के पैनल

- सैंड स्टोन वॉल पैनल

- प्राकृतिक पत्थर की दीवार के पैनल

- मार्बल स्टोन वॉल पैनल

- मार्बल वॉल पैनल्स

- पत्थर जड़ना

- पत्थर मोज़ेक

- संगमरमर

- Stone Minning

- Stone Cutting

- Stone Finishing

- Quick Enquiry

- संपर्क करें

मुझे निःशुल्क कॉल करें

मुझे निःशुल्क कॉल करें