Elegant Natural Stones private Limited

- Home Page

- Company Profile

-

Our Products

- Marble

- Green Marble

- White Marble Tiles

- Indian Marble Slabs

- Marble Tiles

- Indian Marble Floor Slabs

- Indian Marble

- Green Indian Marble Stones

- Natural Stone Tiles

- Indian Marble Stone

- Indian Marble Floor Tiles

- Polished Marble Tile

- Indian Marble Tiles

- Marble Stones

- Black Marble Tiles

- Indian Marble Tile Pattern

- Marble Block

- Marble Floor Slabs

- Marble Flooring Slabs

- Black Galaxy Marble

- Marble Flooring Tiles

- Rajasthani Marble

- Marble Tile Designs

- Marble Kitchen Floors

- Custom Marble Table Tops

- Marble Tile Slabs

- Polished Marble Floor Tile

- Marble Slabs

- Marble Flooring Designs

- Marble Table Tops Designs

- Marble Flooring Pattern

- Marble Flooring

- Marble Table Tops Slabs

- Marble Tile Pattern

- Indian Tile Marble Patterns

- Marble Stone Designs

- Marble Tile Pattern Designs

- Granite

- Granite Floor Slab

- Natural Granite Floor Tile

- Indian Granite Stone

- Indian Granite Marble

- Granite Tile Pattern

- Black Polished Natural Granite Floor Tile

- Granite Stone

- Granite Indian Slabs

- Indian Granite Flooring Slabs

- Granite Stone Slabs

- Granite Table Tops

- Granite Flooring

- Granite Slabs

- Granite Flooring Designs

- Granite Patterns

- Indian Granite Slabs

- Granite Blocks

- Black Granite Floor Tile

- Granite Tile Designs

- Granite Cut Size Slab

- Granite Tile Table Top Designs

- Granite Tile Flooring

- Snow White Granite

- Designer Granite Flooring

- Black Granite

- Indian Granite

- Granite Counter Tops

- Indian Granite Stone Slabs

- Granite Flooring Pattern

- Galaxy Granite Slab

- Granite Stone Design

- Indian Granite Slab

- Granite Tiles

- Indian Granite Tiles

- Baltic Brown Granite

- Kashmirs Gold Granite

- Rajasthan Black Granite

- Alaska White Granite

- Alaska Blue Granite

- Amba White Granite

- Apple Green Granite

- Bala Flower Granite

- Bash Paradiso Granite

- Black Marquino Granite

- Black Pearl Granite

- Blue Granite

- Blue Pearl Granite

- Brazilian Granite

- Brown Pearl Granite

- Butterfly Blue Granite

- Cats Eye Granite

- Cheema Pink Granite

- Chima Pink Granite

- Cheery Brown Granite

- Classic Paradiso Granite

- Coffee Brown Granite

- Colombo Juparana Granite

- Copper Silk Granite

- Desert Green Granite

- Sandstone

- Natural Stone Flooring

- Raveena Sandstone

- Sandstone Flooring Designs

- Natural Sandstone

- Indian Sandstone

- Rough Sandstone Slab

- Natural Sandstone Flooring

- Sandstone Designs

- Sandstone Paving Flooring

- Sandstone Floor Slabs

- Sandstone Slabs

- Sandstone Flooring

- Sandstone Flooring Slab

- Sandstone Garden Flooring

- Indian Sandstones Slabs

- Natural Sandstone Floor

- Indian Sandstone Slabs

- Indian Sandstone

- Rough Sandstone Blocks

- Sandstones Slabs

- Indian Sandstone Flooring

- Agra Red Sandstone

- Autumn Brown Sandstone

- Beige Sandstone

- Chocolate Sandstone

- Dholpur Beige Sandstone

- Dholpur Red Sandstone

- Fossil Mint Sandstone

- Fossil Sandstone

- Kandla Grey Sandstone

- Panther Sandstone

- Pink Sandstone

- Rainbow Sandstone

- Rainbow Teak Sandstone

- Teakwood Sandstone

- Teak Sandstone

- Raj Green Sandstone

- Ravina Sandstone

- Yellow Mint Sandstone

- Real Grey Sandstone

- Camel Dust Sandstone

- Dholpur White Sandstone

- Lalitpur Yellow Sandstone

- Slate Stone

- Slate Stone Marble

- Slate Stone Flooring

- Slate Paving Patio Slabs

- Indian Natural Slate Stone

- Indian Slate Stones Slabs

- Indian Slate Stone

- Indian Slate Stone Slabs

- Slate Stones

- Indian Slate Stones

- Silver Grey Slate Stone

- Slate Stones Flooring

- Slate Stone Patterns

- Slate Stone

- Natural Slate Flooring

- Slate Stone Slabs

- Indian Slate Stone Paving

- Slate Paving Slabs

- Natural Slate Stone

- Slate Stone Designs

- North Indian Slate Stones

- Limestone

- Bidasar Stone

- Indian Rainforest Marble

- Indian Bidasar Stone

- Indian Bidasar Marble

- Indian Rainforest Slabs

- Indian Bidasar Slabs

- Indian Rainforest Marble

- Indian Bidasar Slabs

- Bidasar Marble Slabs

- Bidasar Marble Slab

- Rainforest Marble Slabs

- Rainforest Marble Stones

- Rainforest Marble

- Natural Bidasar Stone

- Bidasar Stone

- Bidasar Flooring Marble

- Bidasar Rainforest Marble

- Bidasar Green Marble Slab

- Bidasar Green Marble Stone

- Bidasar Indian Marble

- Bidasar Marble Stone

- Bidasar Flooring

- Bidasar Marble Slabs

- Rainforest Green Marble

- Natural Bidasar Marbles

- Bidasar Green Marble

- Bidasar Rainforest Yellow Marble

- Bidasar Rainforest Brown Marble

- Bidasars Stone

- Bidasar Marble Flooring

- Bidasar Marble

- Bidasar Brown Marble

- Bidasar Green Marble Slabs

- Bidasar Rainforest Green Marble

- Bidasar Floor Patterns

- Bidasar Floor Designs

- Quartzite Stone

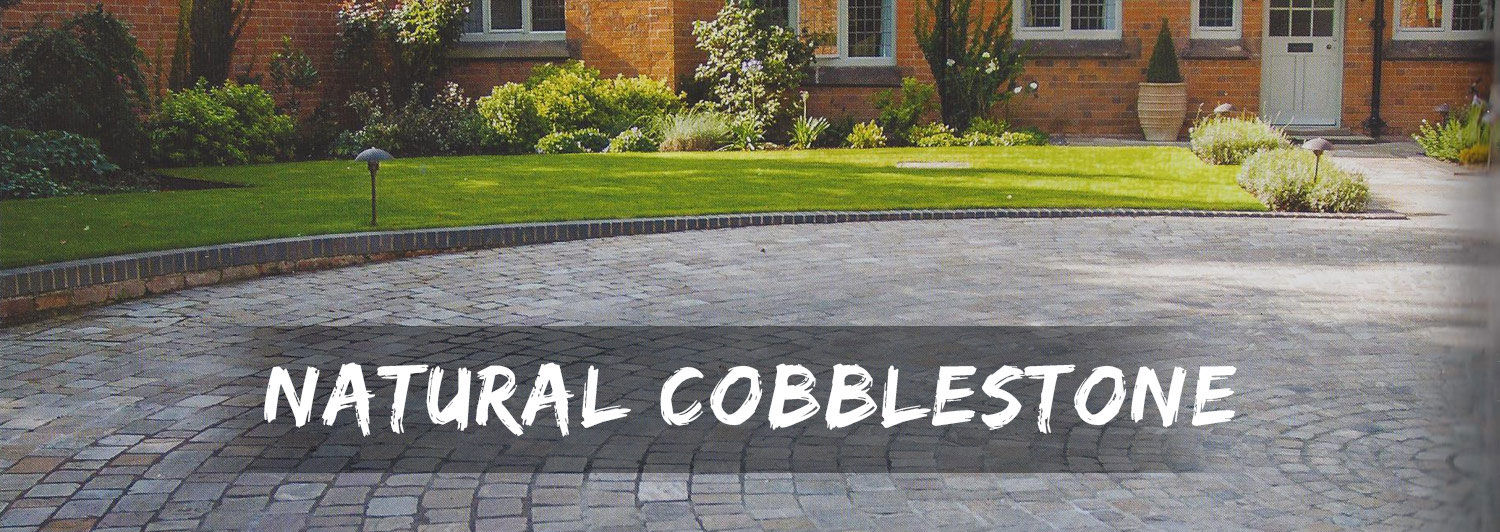

- Natural Cobblestone

- River Pebbles

- Stone Handicrafts

- Indian Stone Handicrafts

- Indian Sandstone Handicrafts

- Stone Handicraft Items

- Decorative Stone Handicrafts

- Marble Handicrafts

- Stone Handicrafts

- Marble Handicraft Items

- Marble Pots

- Stone Handicrafts Designs

- Stone Handicrafts Patterns

- Traditional Stone Handicrafts

- Marble Flower Pot

- Stone Marble Handicrafts Designs

- Natural Stone Handicrafts

- Sandstone Bases

- Indian Stone Bases Items

- Indian Marble Stone Bases

- Indian Sandstone Bases

- Indian Stone Bases

- Marble Bases

- Marble Sandstone Bases

- Sandstone Patio Base

- Natural Sandstone Bases Items

- Sandstone Bases

- Sandstone Bases Designs

- Carved Stone Base

- Stone Bases Items

- Sandstone Bases Items

- Sandstone Bases Patterns

- Stone Jali

- Stone Veneer

- Stone Fireplaces

- Indian Sandstone Fireplace

- Indian Marble Fireplaces

- Indian Marble Stone Fireplaces

- Antique Marble Fireplaces

- Stone Fireplace Mantels

- Stone Crafted Fireplaces

- Stone Fireplaces Designs

- Marble Fireplaces

- Stone Fireplaces

- Natural Stone Fireplace

- Marble Carving Fireplaces

- Marble Stone Fireplaces Pattern

- Marble Stone Fireplaces

- Sand Stone Fireplaces

- Marble Paintings

- Stone Planters

- Indian Marble Stone Planters

- Indian Natural Stone Planters

- Indian Stone Planters

- Indian Sandstone Planters

- Indian Marble Planters

- Stone Garden Planters

- Marble Stone Planters

- Natural Stone Planters

- Stone Planters Designs

- Stone Flower Planters

- Outdoor Stone Planters

- Stone Big Planters

- Stone Planters Patterns

- Stone Pots

- Stone Pillars

- Indian Natural Stone Pillars

- Indian Stone Pillars

- Indian Marble Pillars

- Indian Stone Pillars Round

- Natural Stone Marble Pillars

- Natural Stone Pillars

- Marble Stone Pillars

- Granite Stone Pillars

- Stone Pillars

- Stone Pillars Designs

- Carved Stone Pillars

- Sand Stone Pillars

- Marble Columns

- Stone Pillars Patterns

- Stone Fountains

- Indian Stone Fountains

- Indian Marble Stone Fountains

- Stone Garden Fountains

- Marble Fountains

- Marble Stone Fountains

- Natural Stone Water Fountains

- Stone Fountains

- Sandstone Garden Water Fountains

- Small Stone Fountains

- Natural Stone Fountains

- Marble Fountains Designs

- Marble Stone Fountains Designs

- Stone Fountains Designs

- Stone Fountains Patterns

- Stone Figures

- Stone Table Tops

- Indian Marble Table Tops

- Indian Stone Table Tops

- Table Top Tiles

- Marble Stone Table Tops

- Marble Stone Table Tops Designs

- Round Marble Table Top

- Stone Table Tops Designs

- Marble Table Tops

- Natural Marble Stone Table Tops

- Marble Slab Table Top

- Natural Stone Table Tops

- Stone Table Top Slab

- Stone Table Top

- Indian Marble Stone Table Tops

- Stone Kerbs

- Stone Wall Panels

- Indian Natural Stone Wall Panels

- Indian Stone Wall Panels

- Indian Marble Wall Panels

- Wall Panels Stones Patterns

- Stone Tiles

- Wall Panels Stone Designs

- Stone Wall Tiles

- Stone Wall Panels Tiles

- Traditional Stone Tile Wall Panels

- Stone Wall Panels

- Decorative Stone Wall Panels

- Sand Stone Wall Panel

- Natural Stone Wall Panels

- Marble Stone Wall Panel

- Marble Wall Panels

- Stone Inlay

- Stone Mosaic

- Marble

- Stone Minning

- Stone Cutting

- Stone Finishing

- Quick Enquiry

- Contact Us

Call Me Free

Call Me Free